Blog, Kashmiri Culture

Making of Kashmiri Pashmina Shawls

Combing the Changthangi or Kashmir Pashmina

The Pashmina is harvested during spring season, when animal naturally shed their under coat. On the basis of weather conditions and season, the goat starts moulting over a period from mid March to late May. It is done manually by combing

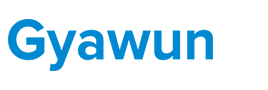

Sorting or De- Hairing

Sorting/ dehairing means separation of undercoat/ pashmina from guard hair. The sorting of pashmina is done manually, mostly by women folk

Combing Again

Raw pashmina is having lot of impurities like vegetable matter, sloughed epithelial cells, dust, etc. with it, which needs to be removed for efficient processing. The objective of combing is to remove these impurities and parallelize the fibres.

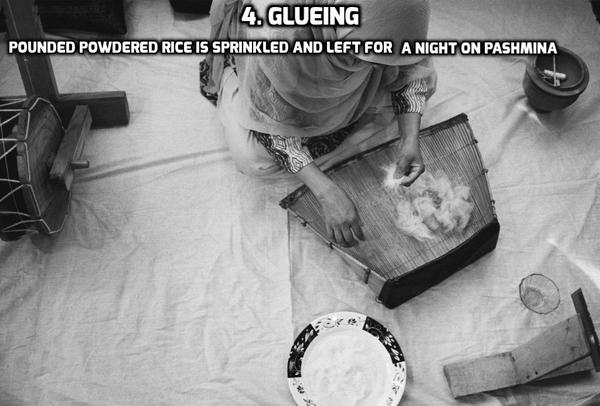

Glueing

Glueing means application of glueing material to pashmina. This is done by applying pounded rice. The pashmina is placed in a container over which pounded powdered rice (kharioat) is sprinkled and left on pashmina for a night or two. The purpose of glueing is to provide extra strength, moisture and softness to the fiber

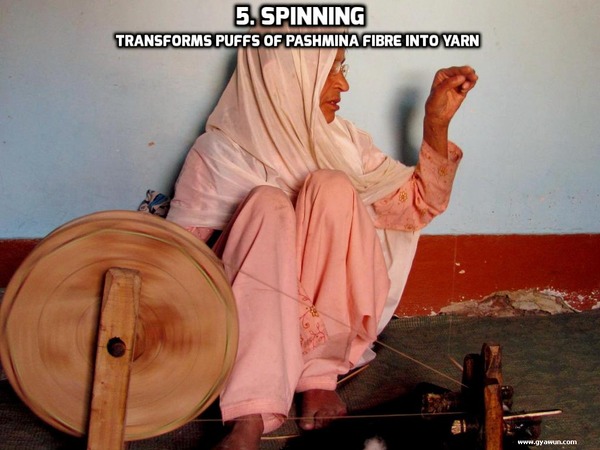

Spinning

Spinning converts continuous untwisted strand of fibers into required yarn count and twist suitable for further processing. Traditionally, spinning is being carried out on a spinning wheel termed yander or charkha

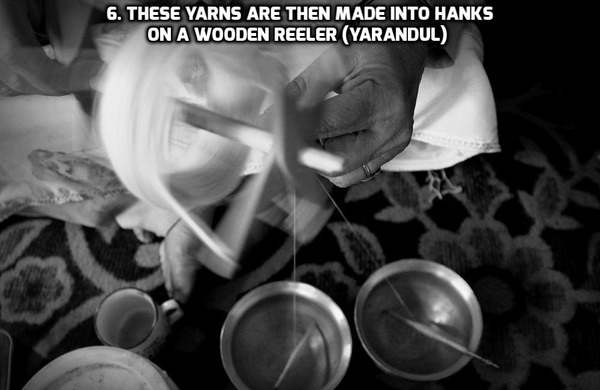

The yarn produced by spinning wheel is spun on a grass straw or any light holder locally called phumblet. The spun yarn on these holders is doubled on hand reeler. The double yarn is subjected to twisting/pilling on the same charkha with the direction of twist reversed. These yarns are then made into hanks on the wooden reeler locally called Yarandul

Weaving is started with opening of the hanks on the large wooden stand locally called thanjoor and is mounted on a wooden spindle termed as prech

Four to six rods are being erected into the ground. Two persons work together and transfer yarn from prech onto the iron rods by using sticks. This process is called yarun About 1200 threads are stretched in this manner to form warp locally called yaen which is enough for 4 to 6 shawls.

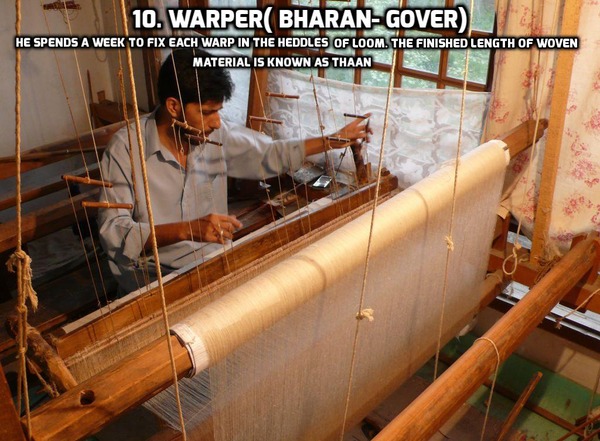

The warp (yaen) is now given to wrap-dresser (Bharan-gour) to stretch the wrap. He spends a week or so to fix each wrap thread in the saaz (heddles of the loom). The finished length of woven material is known as thaan. This is washed in cold water with powdered soap nut, reetha or of special soap made from similar herbal ingredients.

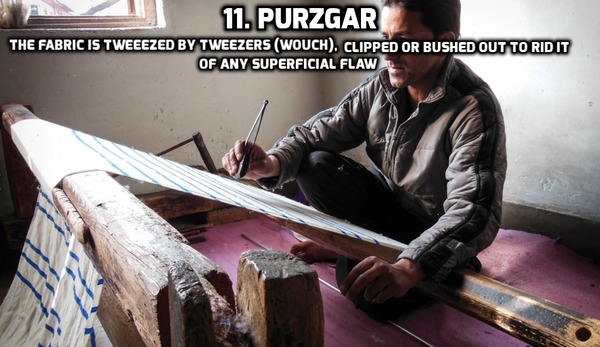

The washed fabric is now sent to the purzgar. Here the fabric is tweezed, clipped or brushed out to rid it of any superficial flaw on the surface.

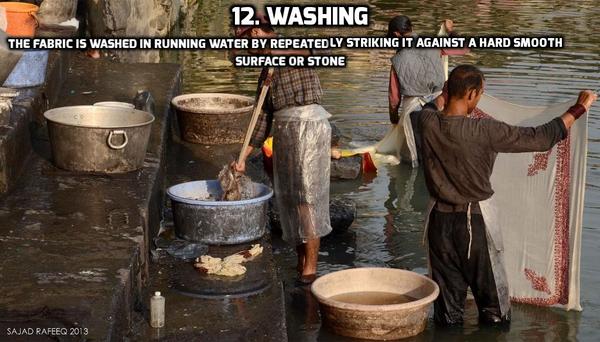

The fabric is now washed by washer man or dhobi who washes the fabric in running water, by repeatedly striking it against a hard smooth surface or stone. The fabric is rolled and left stretched for several days. It is then ironed packed in plastic bags

Text credit: here